A water trap will remove larger droplets of water but the air coming through can still be moist.

Air can only carry a certain amount of moisture but it depends on it's temperature, cool air can carry less. It's known as the dew point.

Industrial dryers chill the compressed air to below its dew point, the water drops out then the air is warmed before it leaves the dryer. As long as the air doesn't drop below the temperature it was chilled to, no more moisture drops out.

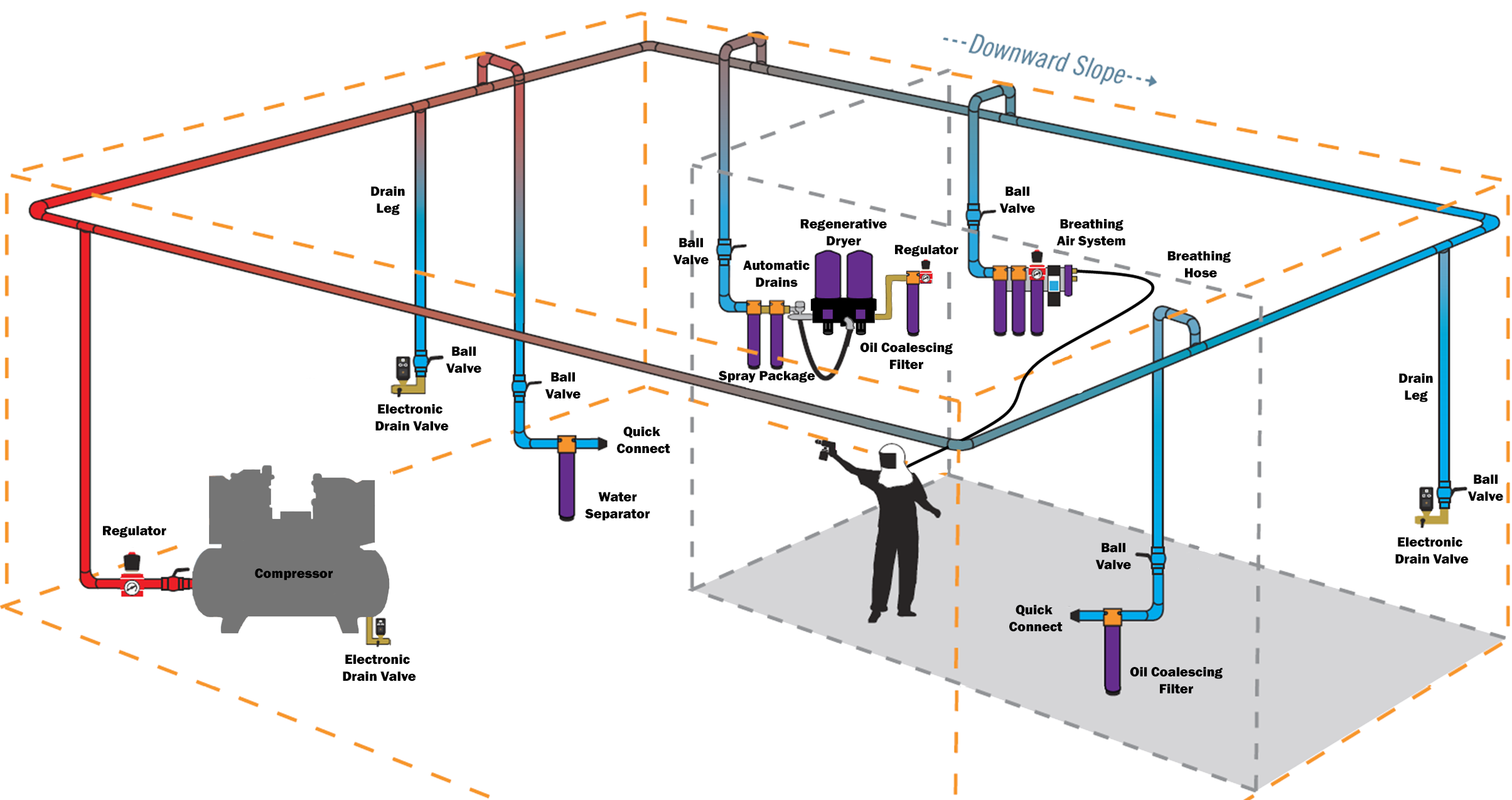

With a delivery system in a factory you take compressed air from the top of the large diameter main pipe, then turn 180degrees down to where it's needed. Drain legs (if needed) come from the bottom of the main pipe. The main pipe should be at a slight angle so any water is guided to a drain leg

I've been in the pneumatics industry for over 30 years and have never seen anything like the layout below and don't understand what would be achieved by the pipework (apart from generating business for the company that sold the pipe & fittings )

Using a large receiver can get moisture to drop out of the air initially as it's cooler than the incoming air. Remember to drain the receiver regularly though.

I went to use a small Junair silent compressor at a company I worked at and thought I'd drain the receiver....about 5 litres of rusty water were removed ! It had been used for a long term test on some pneumatic equipment then put back into stock.

A standard pneumatic filter regulator has stationary blades inside that spin the incoming airflow, water droplets are thrown to the inside surface of the bowl and can be manually drained out as it builds up (some have semi or fully automatic drains). They don't 'dry' the air.

You can buy in-line dryers but.....they are quite large, very expensive and restrict airflow.

I use a small compressor for spraying and don't get water coming through (more by luck than judgement) but it will depend on ambient temperature and other factors.

Colin

Reply With Quote

Reply With Quote

Bookmarks