Misquoting Jeff Goldblum in Jurassic Park, "Life, uh, gets in the way". It's nice to be in a position to work on it again.

Answering a question I had earlier in case it helps somebody in the future: where do you find the part number on a Land Rover Series wheel rim? It's on the outer face between stud holes. They are apparently easily covered by multiple layers of paint, hence not being able to find it on the first rim I looked at. To be fair, I still haven't found it on the other rim, but at least I know where to look.

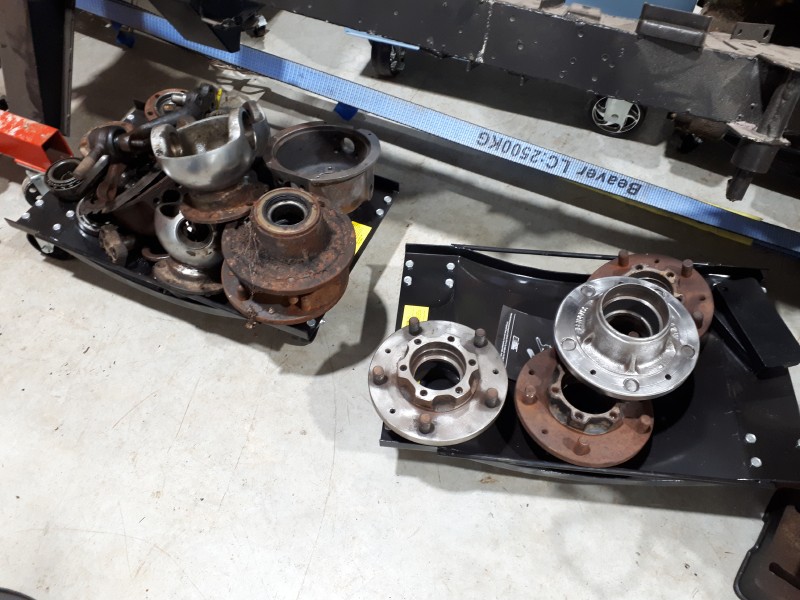

Not much progress today, just cleaning 65-odd years of gunge and grease off parts so they can be blasted and repainted. Hopefully this process will become much less time consuming once the degreaser for my parts washer arrives. I also need to purchase some softish brushes, screwdrivers and rags are only so good.

Cheers,

Martin

Reply With Quote

Reply With Quote

Bookmarks